Featured Resources

Featured Products

3D Scanners & Software

With a broad scope of 3D scanning technologies, we offer you the perfect technology solution for delivering precise digital 3…

Article

Jay Leno and Team Put Digital Manufacturing to the Test

Jay Leno, comedian and celebrity host of NBC’s The Tonight Show from 1992-2014, is almost as well known for his beloved class…

Featured Products

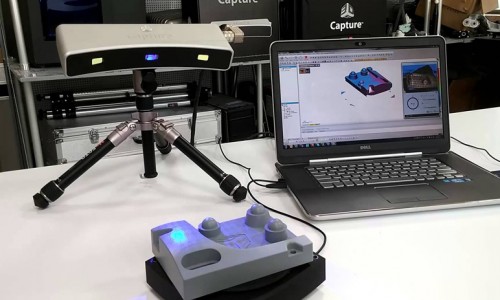

Integrated, Industrial-grade 3D Scanning with Geomagic Capture

Bring physical objects directly into CAD, supercharge your product development process, and automate precise 3D inspection wi…

Featured Products

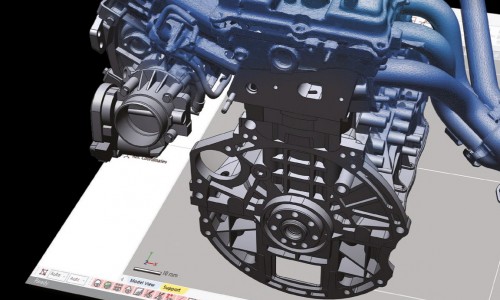

Reverse Engineering with Geomagic Design X

Geomagic Design X, the industry's most comprehensive reverse engineering software, combines history-based CAD with 3D scan da…