That’s a Bad Boy

When Robert Foster and Phil Pulley set out in 1998 to build a zero turn mower, they had one goal in mind, make a no-nonsense, reliable and durable mower at an affordable price. After building their first prototype in a garage and testing it out, an associate stepped off the mower and commented, “That’s a bad boy”. Needless to say, the name stuck, and Bad Boy Mowers has built a reputation in the industry for being one of the best built and most comfortable mowers in the business.

Bad Boy Mowers now operates in a manufacturing facility with over 600,000 square feet located in Batesville, Arkansas. They pride themselves on having the ability to make 95% of their manufactured parts in house, allowing them to adapt quickly and build custom products.

“We are a small company that can adapt to changes quickly. We can come up with a new product and get it out quicker than a large company, and we can customize as needed,” adds Jason Conner, Design Specialist.

Innovation at Its Best

Bad Boy Mowers attention to detail and constant drive for innovation are the keys to their success in the power equipment industry. Every mower is built with the highest standards for quality and durability in mind, something each employee is committed to providing on a daily basis.

By using the most innovative equipment and products to create their mowers, Bad Boy can not only ensure they stay ahead of the competition, but help to keep their manufacturing process lean, allowing them to provide an economical product to their customers, without sacrificing the high level of quality they demand.

One product that is vital in helping Bad Boy control their costs is Autodesk Inventor, their 3D design tool, provided by D3 TECHNOLOGIES.

“Designing our products in a 3D environment allows us to create a product that will work in a real environment. We don’t have to waste money on materials by creating prototypes and testing them in the field. Inventor allows us to test for interferences and make changes quickly and easily before we manufacture,” comments Jason Conner.

The Inventor Advantage

Before Bad Boy Mowers’ designers began using Inventor, they built each single part, tested it, and fit it together until they had a finished product, a painstaking process that was cut dramatically by the addition of 3D design.

“When we decided to stop outsourcing and build the majority of our products in house, Inventor played a large part in making our processes a lot easier, especially when it came time to customize our products,” added Jason.

Bad Boy Mowers is now able to streamline their manufacturing process, enabling them the flexibility and efficiency needed to stay ahead in the market.

Above Left: Bad Boy Mowers ZT series, designed for smaller residential lawns.

Above Right: Bad Boy's new All Electric MTV.

The Support System

The need for Autodesk Inventor software was first created when Bad Boy Mowers decided they needed a better looking product for their parts manuals. They wanted their products to look as superior to the competition as they were in real life.

D3 TECHNOLOGIES was there to show them the latest in 3D design technology.

Jason added, “D3 was able to get us updated on the Autodesk product and show us how to use it in a real-world environment. The products we create in Inventor are as close to the real thing as possible.”

D3 is also there as a support system to Bad Boy Mowers, constantly providing Autoesk support and keeping them up to date on the latest software changes.

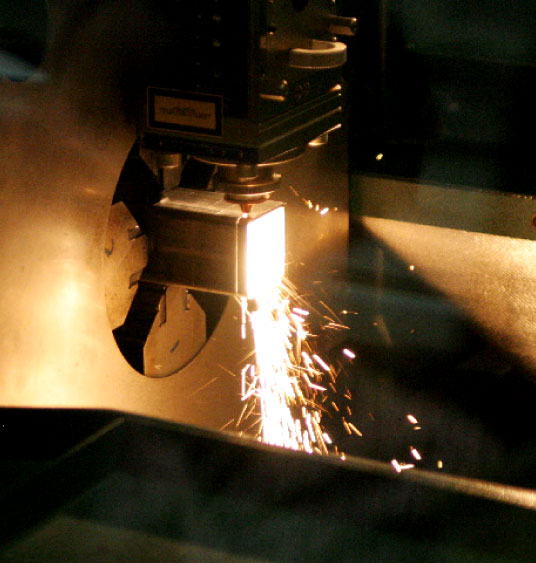

Above: Using the latest in laser technology, the BLM Adige Tube Laser System provides Bad Boy Mowers with a high speed, precise cutting system.

Opening the Door for New Opportunities

Bad Boy Mowers doesn’t plan on sitting back and taking it easy anytime soon. They have recently expanded their product line to offer electric multi-terrain vehicles (MTV). These revolutionary new MTVs can be plugged into any 110 volt electric outlet to be charged. Bad Boy also hopes to have a gas powered version available soon.

But they don’t stop there; Bad Boy Mowers is also looking to add a residential type mower that will be more affordable for anyone with smaller yards and properties, a smaller version with all the power and durability Bad Boy has become known for.

Special thanks to Nick Barber and Jason Conner for their contributions to this article.

If your company would like to participate in a D3 Customer Success Story, or if you would like to learn more, please contact D3.