Based in Louisiana, CellXion is a division of Sabre Industries, Inc., the largest telecom shelter manufacturer in the world. CellXion designs and manufactures a full line of concrete, structural steel, and ultra-light aluminum shelters. CellXion also provides mobile, panelized and field-erectable specialty products. Their services include equipment integration and complete turnkey construction, sometimes built entirely to the customer’s specific needs.

Using the Right Tools

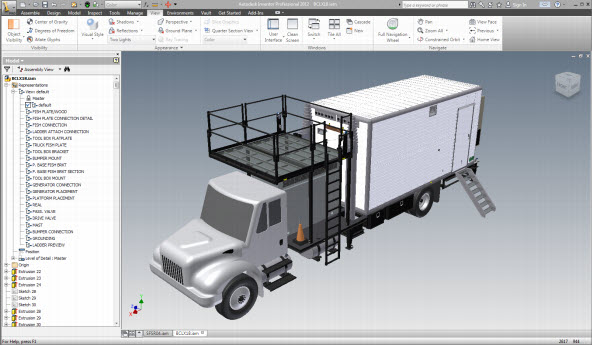

CellXion uses AutoCAD, Autodesk Inventor and Autodesk Vault to design projects, produce drawings and securely store files. With these tools in place, engineers can visualize their designs in 3D before they’re real – called digital prototyping. They can also migrate entire parts libraries and design documentation from 2D to a 3D environment. This is done more seamlessly because the tools are all Autodesk.

Staying Up-to-Date

One of the ways CellXion stays ahead of its competition is to produce designs that work better, faster. “There are many factors we can control to earn our customers’ business,” says Lukasz Drozdz, CAD System Administrator at CellXion. The engineering department uses Autodesk Engineer-to-Order to automate design and drawing tasks that they frequently use, instead of doing the same tasks manually over and over. “With the help of D3 Technologies, we have also implemented a sales automation application that allows us to create simple drawings by turning engineering rules that we apply every day into lines of code,” says Drozdz. Automating tasks in both the design and sales stages can help companies produce accurate quotes faster for their customers.

Another way CellXion stays on the cutting edge is through their Subscription to Autodesk products. With Subscription, CellXion always gets the latest software and technology available. When a new development in technology allows them better or faster capabilities, CellXion is able to use that technology right away.

Looking Toward the Future

CellXion has been taking their business to new heights by diversifying their products and reaching out to new industries, including oil and gas, utilities or green energy. This new step brought new challenges to the engineering department, with entirely new designs that are sometimes unique to the individual customer. For these designs, working closely with the customer to produce exactly what they need is critical. CellXion feels that a digital prototyping approach is the best solution in these situations. “Recently, for one of our customers, we came up with the design fully in 3D,” says Drozdz, “We let them virtually walk through the building and see how it is going to be. It took several iterations and some significant changes before we finalized the design. It happened before we engaged production and allowed us to avoid costly mistakes and changes.” This amazing technology is the reason CellXion, along with many other manufacturing companies, are turning to Digital Prototyping to show customers their designs before heading to the shop floor with them. Saving time and money, engineers are still able to wow the customers with their designs, and make sure it’s what the customer really wants.

A Physical Vs. Digital Prototype

Digital Prototyping is a revolutionary approach to product development that lets you design, visualize, and simulate products rapidly and cost-effectively. Help grow revenue, spur innovation, and deliver quality products faster than ever with Digital Prototyping. Check out CellXion’s real-world example of digital prototyping on the left, compared with a physical shelter on the right.

If you are interested in how Digital Prototyping, automation, or subscription could help you win bids and stay ahead of the competition, or if you would like to participate in a D3 Customer Success Story, contact D3 today.